Like ordinary printed packaging products, for a packaging box, it takes 7 steps to make it from artwork to reality. They are design, proofing, material selection, printing, surface treatment, die cutting and mounting.

1. Design: Divided into structural design and graphic design. Most of the structural design is done by our company. The customer only needs to give him his idea, or refer to the picture, to provide the product information to be packaged, and our designer will do the structural design. Most of the graphic design is completed by the customer. Generally, our company provides the texture file. The customer designs the pattern suitable for the box according to the advertising packaging requirements they want to achieve, combining the customer’s company culture, customer brand concept, and product characteristics.

2. Proofing: Make samples according to the drawings. Gift boxes pay attention to beautiful appearance, so the colors of the versions produced are also varied. Usually, a gift box of a style has not only 4 basic colors but also a few spot colors, such as gold and silver. These are all spot metal colors.

3. Material Choose: The general gift box is made of hardboard or rigid board. High-end wine packaging and gift packaging cartons. Mostly, cardboard with a thickness of 3mm-6mm is manually pasted on the external decorative surface and bonded to form.

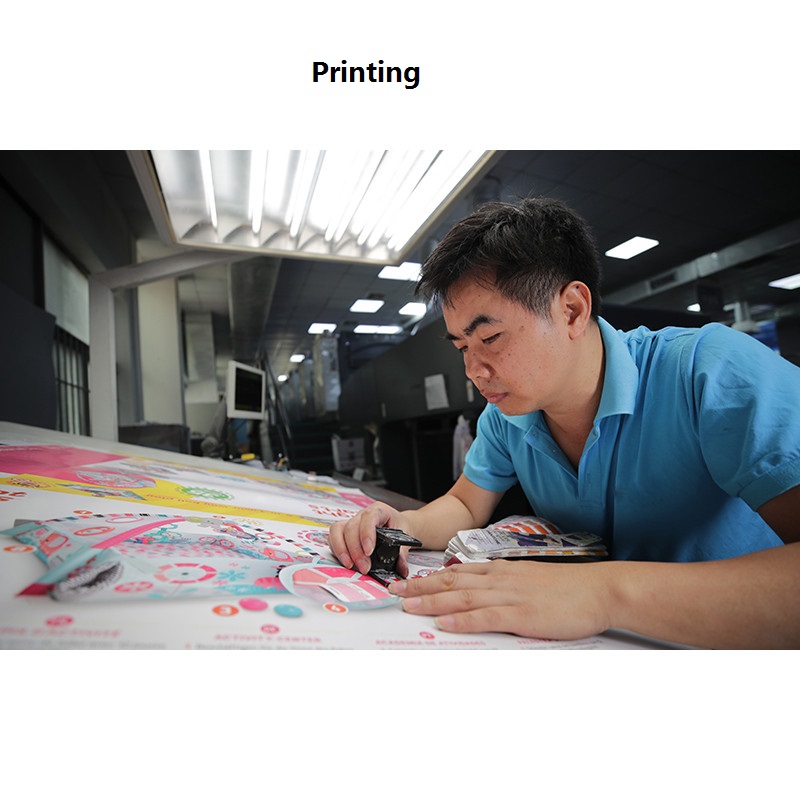

4. Printing: The gift box is only printed with hand gluing paper. The mounting paper will not be printed, almostly it is only dyed. Because the gift box is an outer box, the printing requires high quality. The most taboo is color difference, ink dots, and rot. These shortcomings that affect aesthetics.

5. Surface treatment: The wrapping paper of the gift box usually needs to be surface treated, and the common ones are glossy lamination, matte lamination, UV finish, glossy varnish, and matt varnish.

6. Die Cutting: This is an important part of the printing process. If the beer is accurate, the die must be accurate. If the beer is inaccurate, the beer is biased, and the beer is constant, these will affect the subsequent processing.

7. Mounting: Usually the printed matter is mounted first and then beer, but the gift box is first beer and then mounted. One is afraid of getting flowers and wrapping paper, and the other is that the gift box pays attention to the overall beauty. The gift box mounting paper must be handmade to reach a certain beautiful level.

Post time: Oct-11-2021